Wondering how to recycle more in a warehouse environment? Distribution centres, supply chain management companies and even storage warehouses can generate a considerable amount of waste material from packaging, meeting orders, assembling items and inventory management. These centres often operate at high-volumes, all-day, every day; therefore, any downtime would result in a loss of their revenue.

The problem with these businesses, however, is that they contribute significantly to the amount of waste cardboard, paper and plastic that this country produces. Due to the size and scale of these distribution sites and warehouses, implementing a sustainable waste management program that spans such a large area needs meticulous planning.

Until now, our global economy has largely depended on a linear ‘take-make-use-dispose’ system in which valuable natural resources are extracted, turned into products and then discarded at the end of their service life. As the limitations and damaging consequences of this system become glaringly apparent, so too does the urgent need to rethink it. The economy of the future must meet the needs of a growing population within the confines of diminishing critical resources. A circular economy is a welcome, essential, sustainable alternative to a traditional linear economy, where resources have a long life value within the economy system, by being designed for longer lifetimes, repair, recovery, reuse and recycling.

Most organisations have a warehouse/distribution centre/pick pack operation area, and starting your drive to sustainability here helps to translate the ‘circular economy’ into something that can flow through the rest of your business, and even spread the ‘sustainable vibes’ to other organisations like yours. Transitioning to a circular organisation requires systems-level change, and must have buy in from the decision makers, even involving collaboration along supply chains and between sectors. The warehouse is a great environment for starting this.

Download the free, printable guide here to successful recycling in a warehouse environment

Recycling is one of the easiest ways to help your warehouse go “green”. Not only does sending less to landfill reduce your carbon footprint and make your business more sustainable but it can also reduce running costs, and reduce waste collection costs – general waste is always more expensive than recycling. There are a number of simple choices your business can make to reduce your environmental impact without affecting productivity or the bottom line.

Recycling is one of the easiest ways to help your warehouse go “green”. Not only does sending less to landfill reduce your carbon footprint and make your business more sustainable but it can also reduce running costs, and reduce waste collection costs – general waste is always more expensive than recycling. There are a number of simple choices your business can make to reduce your environmental impact without affecting productivity or the bottom line.

Here are our simple tips to help you REDUCE, RECYCLE, REUSE in your warehouse.

1. Assess: Start by identifying areas where waste can be reduced or reused

The first thing to do is to examine where you currently produce the most waste in your facility, and consider whether alternative solutions would allow you to reduce your waste output. Where waste is unavoidable, work out what you can do to first reuse, then reduce, then recycle that remaining waste.

Think about other consumables that you use day to day in the warehouse. Batteries, for example, can be recycled easily. Can you reduce the amount of paperwork you print out by relying on electronic devices?

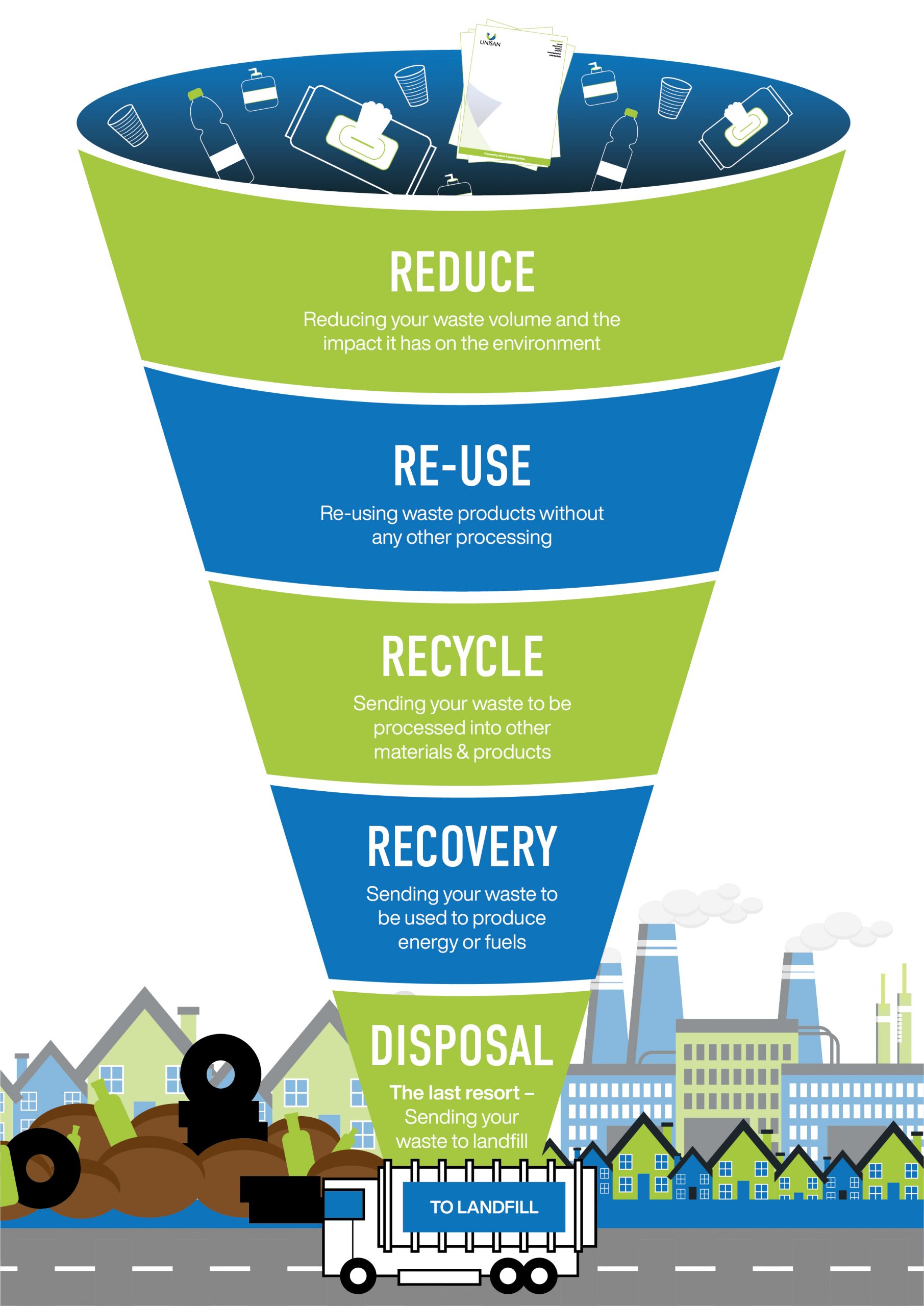

Think about how well you recycle at home – It’s time to bring that circularity mindset to your workplace. Even if you are net zero, or well on the way to net zero, there’s always room for improvement. It is likely you have the opportunity for greater circularity in your business. It is becoming more obvious it is time for change in order to preserve our planet for future generations. Your organisation should first identify opportunities to increase sustainability, from reducing resource consumption, to procuring circular products and services or packaging, reducing or reusing waste, and of course sending all that’s left to recycling, rather than landfill or incineration. Using the hierarchy of waste is a great way to prioritise how to reduce your waste, working towards being a zero-waste facility, and minimise the negative impact your waste has on the environment.

2. Reduce your packaging and consumables

Packaging is the single biggest contributor to warehouse waste and the most important factor to address to improve your waste management. Some packaging is unavoidable, but thinking outside the box can help you see ways to make reductions in waste. Using less packaging means less waste. Make sure boxes are the right size for goods so that you can minimise the need for packing material such as loose fill chips or air cushions. Consider whether goods need individual plastic wrapping, can be wrapped together or placed directly in boxes. For essential packaging, reducing your reliance on plastic and switching to biodegradable packaging materials will make a significant difference to your waste output.

3. Switch to reusable or returnable packaging

Some packing materials can be reused. Attached lid containers (or ALCs) are ideal for use as secure and reusable return packaging, particularly for business to business supply. Encourage businesses you work with to participate in your sustainability scheme by returning your packaging for reuse. Pallets can also be reused again and again.

4. Invest in the best recycling and waste containers for your distribution centre

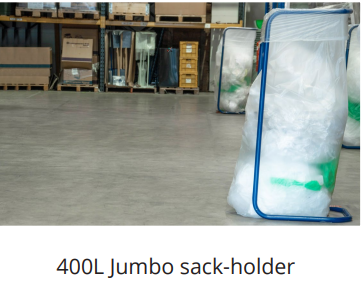

Refreshing your recycling ‘binfastructure’ can get costly, so it’s important to ensure that you get the most out of a new system, without breaking the bank. For optimum efficiency, you’ll need to carefully

consider which bins you use in which environment. Simply having the same bins throughout your facility for use in all applications & areas will result in a compromise in both your recycling & operational efficiencies. For example, the key thing to consider in processing and packaging areas will be waste volume. Depending on your industry, this type of environment will often create high volumes of bulky packaging waste which can be difficult to manage. In these circumstances it’s vital to have a solution which can easily cope with such high waste volume. If you use a waste compactor, then you’ll need a solution compatible with that, for example perforated liners which allow the air to be easily pushed out when the waste is compacted.

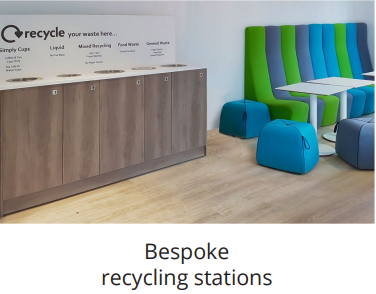

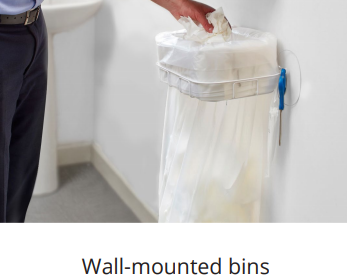

In a front-of-house environment, however, the needs will be completely different, and aesthetics will be far more of a priority, but waste volumes will be far lower. Within food preparation and staff eating areas, you’re likely to have a range of different waste streams, including a range of different plastic packaging, and of course food waste.

The first thing to consider here is what waste streams you have collected at your site. Obviously, if you only have general waste & mixed recycling collected, there’s no point in spending money on a recycling scheme that segregates recycling into 5 separate streams. If you want to segregate your waste better than you are currently, then the first thing to do is talk to your waste collector, or maybe even find a new one. Once these back-of-house processes are set up, it’s time to start thinking about how to effectively segregate the waste. You may even consider using multiple waste collectors.

Industrial & manufacturing environments often produce a large amount of a particular waste stream. Processing & packaging areas will often have a particular type of plastic, or other packaging waste, produced in large quantities. If the quantity is high enough, it could be worthwhile recycling this waste, even though it’s typically put in general waste. However, there are often other waste streams

that you may be producing a lot of. An analysis of your waste may reveal that there could be an opportunity to recycle a particular item that would not usually be recycled. Always bear in mind that almost anything can be recycled, but it’s often not commercially viable unless you produce large quantities.

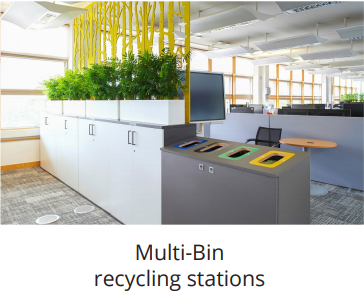

5. Ensure recycling bins are placed in the optimal locations

There are 2 main factors that will affect this: the density of your staff and they type & volume of waste you produce. For example, a packaging area will typically have a density of people, and a high volume of waste created. A modern warehouse, however, with advanced automation and a very low density of people, will create far less waste, and therefore have very different needs. The type of operation in a particular area will also determine how many bins will be needed. For example, in an area where time is at a premium and maximum employee efficiency is vital, you won’t want your staff walking too far to dispose of their waste, so individual bins next to each worker’s space may well be worth the investment. In other areas, however, it may make more sense to have higher-capacity bins, but less of them.

In order to make a recycling scheme successful, it has to be as effortless as possible for workers to carry out. In large distribution centres, recycling containers on dollies can make it quicker for employees to dispose of waste as they work. Alternatively, use dedicated cage trolleys to hold cardboard waste (the most common type of recyclable warehouse waste) on its way to larger recycling bins as cage trolleys can easily be moved up and down the aisles.

It is important that recycling bins are placed throughout the warehouse and that at each waste disposal station there is a bin for each type of recyclable waste.

6. Signage is everything – Ensure recycling bins are clearly labelled

Signage is everything! It’s the signage that can make or break the success of a recycling scheme. This needs to be given careful consideration, especially if you’re starting to recycle more or

different waste streams than before. To increase engagement and therefore increase your recycling rates & decrease general waste collection costs, we have 3 top tips:

KEEP IT CONCISE

It may be tempting to have long lists of what can & can’t go in each waste stream, thinking that this makes it very clear to staff what goes where. In

reality, however, staff are unlikely to read every word, and the really important information can get lost in the noise. It’s usually more effective to have literature in the form of a poster near the station

giving more details of the waste streams and keeping the signage on the bin itself as simple and concise as possible.

MAKE IT CLEAR

Everything about the design of your recycling scheme should be designed to make recycling as easy as possible for your staff, thereby increasing recycling rates & reducing contamination.

We recommend colour-coding the waste streams to make things as clear as possible. Where possible, use the WRAP colours for waste streams. The Waste Resource Action Program

(WRAP) is a governing body which seeks to standardise waste recycling across the country, by using standard colours, symbols & signage. You’ll recognise these symbols & colours from

your household recycling, especially at your local civic amenity work, but by using the colours & symbols where possible, you’ll make it easier for staff to centre. These waste streams won’t always

perfectly translate into how you recycle at identify waste streams.

MAKE IT SPECIFIC

If there are certain items that your staff are repeatedly disposing of incorrectly, then just little more information about each waste stream could go a long way. For example, if employees

are putting shrink-wrap in the general waste stream, you may want something specific to your facility, this will go a long way toward eliminating contaminated saying ‘no shrink-wrap’ on your

general waste aperture. If you can solve problems specific to your facility, this will go a long way toward eliminating contaminated recyclable waste.

7. Communication is key – Educate the staff about your recycling scheme

A well-designed recycling solution will only go so far. If your employees aren’t engaged in your recycling scheme, they won’t buy into it, and your recycling rates will suffer. A successful recycling campaign must be designed with staff engagement in mind. So here are some proven tips to get your staff to buy into your plans.

Teach staff about what items can be recycled and which bins they should use. The easiest way to do this is simply by putting clear WRAP compliant labels on the bins themselves. You should also provide training about the most efficient way to pack goods to keep packaging to a minimum.

COMMUNICATION IS KEY

Do your warehouse staff really know why recycling is important? Do they know how recycling can make a difference, and help protect the planet? Are they aware of your company’s sustainability

goals? Do they realise recycling more can save your organisation money on waste collections? Showing your staff that their efforts are affecting change in the bigger, wider picture, quickly creates more engagement with your recycling bins. Communicating your goals and the results regularly to your team instantly helps you to get buy in. Hold a training session if necessary.

Think about sending weekly ‘remember to recycle right’ emails to your staff, with environmental tips, and messages like “Don’t Forget to Recycle” or “Did you know ____ can be recycled?”

MAKE IT SIMPLE

Don’t over complicate things. Recycling can be complicated, so keep your system as straightforward as you possibly can. You might think that splitting your waste into multiple waste

streams will improve your recycling rates, but this can often lead to confusion among staff instead.

MAKE IT FUN

You might not have thought it possible, but recycling can be fun! By injecting something playful and interesting into your recycling program, you will naturally engage more staff. For some inspiration on how to make recycling fun, check out some of the work by Hubbub, an environmental charity. They’ve run several campaigns designed to encourage recycling & reduce littering among the general public, and

each one is designed to engage people in a fun & quirky way.

INCENTIVIZE STAFF

The age-old ‘carrot for the donkey’ technique. By using bottles & cans reverse vending machines along side your recycling stations, you can reward your employees for doing the right thing. These

machines allow you to set up an incentive system which can reward employees with anything from a discount at the staff restaurant to a donation to charity.

CREATE A GREEN TEAM

You may have a green team in your office building, but what about your distribution centre? Nominate team members who are passionate about the environment for a green team. They

can encourage colleagues, and lead by example, to help change the mindset in your company. This can cause a constant positive force for the campaign, and keep everyone on board

to maintain a culture of recycling and waste reduction. A bit of good-natured competition can also motivate employees to participate, especially when there’s something at stake. Some

companies have created teams by department or building section, and whichever group wins the recycling challenge that month wins something. When targets are set, and results are measured a

sense of competition is likely to kick in. When someone gets ‘caught green handed’ you could reward them. Consider taking photos for a “Recycling Heroes” bulletin board.

8. Continuously improve your warehouse recycling

Different facilities may recycle more of different things. For example, some facilities recycle shrink-wrap & other soft plastics, but some don’t get through enough of these materials to make

it worthwhile. So the percentages of recycled waste may vary significantly. A good guide is that if all waste is correctly segregated, mixed recycling should take up 60-80% of waste volume compared to general waste. However this figure can often vary dramatically depending on the types of waste your facility produces. So if your recycling levels are below this, then your first priority should be improving this.

If your levels of mixed recycling are already good, then there’s plenty more you can do.

Even if you send zero waste to landfill, there’s likely to still be room for improvement. If you remember the hierarchy of waste, your first priority should be to reduce the amount of waste you produce. In this sector alone, you can always improve: in an industrial facility, whatever your industry, there is almost always scope to reduce the waste created by your processes. This alone is a never-ending task. Combine this within reducing waste within the offices & staff eating areas throughout your facility, and you have plenty of improvements to make! However, even when just sticking to recycling, there’s still always room for improvement.

If your mixed recycling rates are already high, then it could be time to look at recycling more waste. For example, start to recycle more types of packaging, or analyse your production processes

to see if there is any scope to recycle a particular waste stream that you produce a lot of, but is currently just added to the general waste.

The reality is that to keep improving your recycling, you’ll need to keep investing in better recycling solutions. Whether that be more or better waste stations, more waste streams collected, or ensuring that your waste is all diverted from landfill, successful recycling is likely to involve some investment. Being prepared and willing for this is important in continuous recycling improvement. However, bear in mind that the most expensive waste collection is for general waste. As more tariffs are placed on waste sent to landfill, the expense of recycling is only going to go down, and the cost of doing nothing is only

going to increase.

As you strive to continuously improve your recycling & waste management, don’t lose sight of the bigger picture. The guiding principle behind all your efforts should be the hierarchy of waste. Never forget that recycling should always be your third option after reducing your waste volume and re-using waste products. If you find that there’s a certain item that you’re putting a lot of into general waste, remember that

the first question to ask yourself is; ‘can I reduce the amount of this waste I produce, or stop it altogether?’. Then see if you can re-use it in some way, then consider if it’s recyclable. Only when you start thinking like this will you really make an impact on your wastes carbon footprint.

Hopefully these tips give some ideas on how to recycle more in a warehouse. Download the free, printable guide here to successful recycling in a warehouse environment.

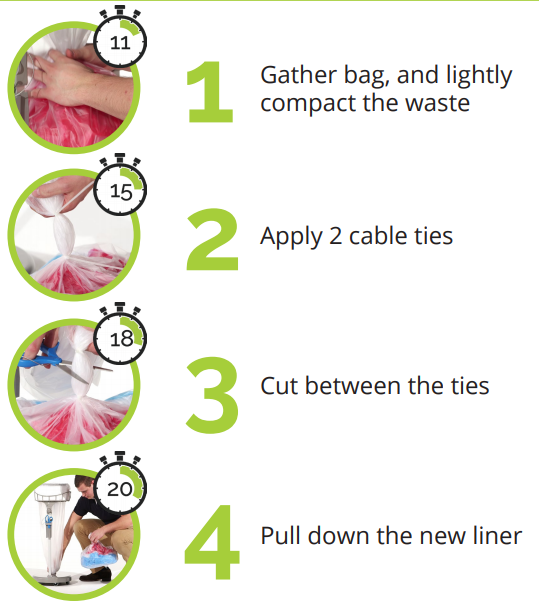

You may have heard of Longopac continuous bin liners. The 20 second bin bag change! Proven to:

- Increase recycling rates by 58%

- reduce labour costs by 38%

- reduce waste collection costs by 35%

- reduce plastic usage by 70%

By switching to the Longopac continuous bin liner system, in 12 months we’ve helped a large UK clothing retailer’s distribution centre to reduce plastic usage by 58 tonnes and the associated carbon footprint by 249 tonnes! That’s just one site, and they are now looking to roll out the system across the UK, due to the easily gained savings!!

See the brochure here to find out more

The Longopac system makes recycling simple and achievable in any environment. With colour-coded liners and options for free-standing signs or lid signage, you can clearly communicate what waste goes where – even in heavy-duty or strictly regulated industrial environments. Translucent liners also make contamination easier to spot and increase accountability.

With Longopac, there’s no wasted space in liners taken up by fresh air! Not only is every liner 100% full, the waste is compacted when removed from the bin, so that all the air is pushed out. This means that the waste takes up much less space in your external bins, therefore reducing the frequency of your collections

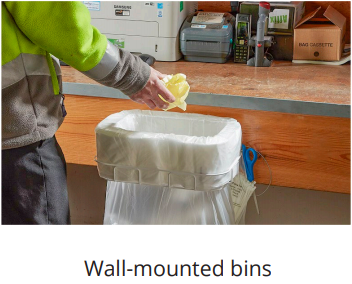

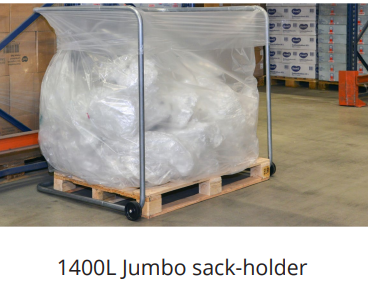

Recycling bin ideas for warehouses and distribution centres…

Processing and packing areas

Production, goods in and storage areas

Office, canteen, break out and washroom areas