29% of all the reported non-fatal work-based accidents in 2016/17 relate to slips and trips. To put this into context, this equates to nearly 200,000 accidents which, with careful management, need not happen. Furthermore, according to HSE, most slips (90%) occur when the floor is wet with water or contaminated with a food product.

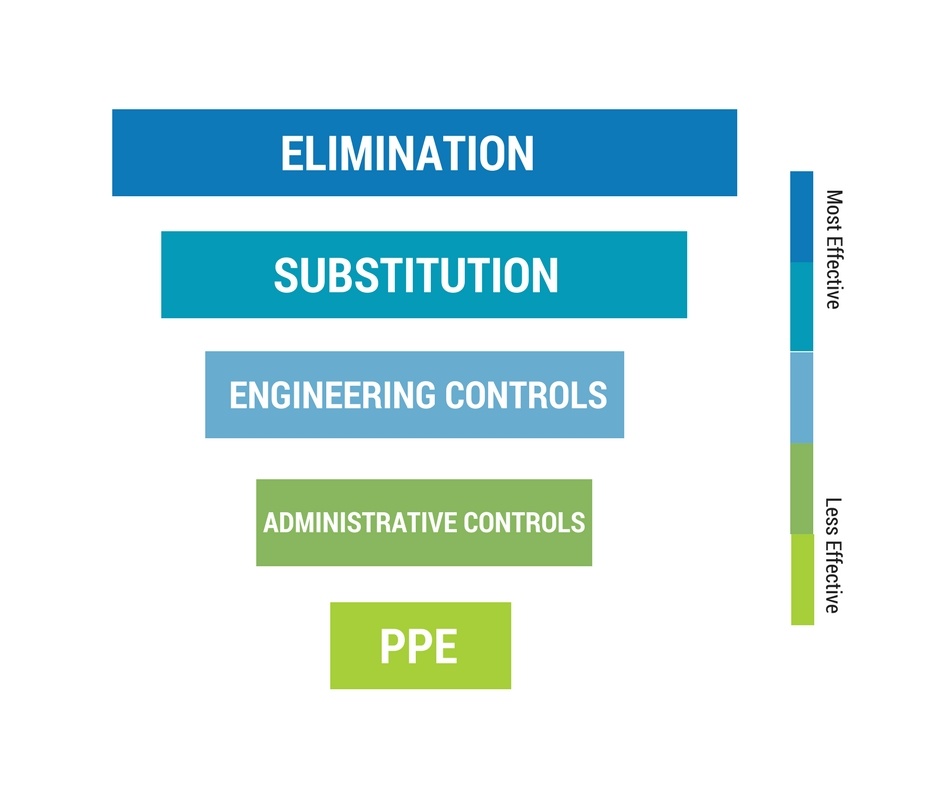

So, to find ways to reduce the risk of slip within your business, it’s common practice to review risks in line with the hazard hierarchy of controls (see image below). Based on this theory, it’s pretty clear that elimination of risk is by far the most effective.

#1 – Reduce contaminants

In almost all slip accidents there is some form of contamination between the floor and the shoe cover or tyre wheel. If floors are kept clean via an effective cleaning method, the risk of slip is greatly reduced.

Of all contaminants, fluid is the most common culprit. On average, 80% of moisture or fluid contamination is carried into production or premises on tyre wheels and shoes, so strategically placing matting that removes (and more importantly retains) moisture is a vital component in reducing slips.

| #2 – Keep on top of cleaning

Keeping floors clean and dry is vital in the battle against slips. However, this is no easy task in a busy production area and many of the customers we speak to spend many hours per shift just to keep on top of the problem. In reality, something is only clean whilst it is being cleaned so traditional cleaning methods can be ineffective. Adopting a solution that automates the cleaning process with each footstep or wheel rotation is an option for those looking to make continuous improvements.

|

|

#3 – Get the right footwear

Are your employees wearing footwear that is appropriate for the specific work conditions that they’re working in? Select suitable footwear as the effectiveness of shoe soles to prevent slips varies considerably. In general, softer soles (eg microcellular urethane with a good pattern) are least slippery on wet floors.

Brands, such as Shoes For Crews (other brands available), are the go-to option for safety shoes. Slip-resistant technology provides the traction needed in industrial and manufacturing environments.

#4 – Clean up any spills immediately

Common sense but failure to clean up straight away increases the chance of the substance penetrating the floor surface. If allowed to penetrate the floor surface, some substances can actually create a more slippery surface even after cleanup.

And, in all instances, please ensure clear spill signage is used.

#5 – Maintain floor condition

Looking after your floor not only increases its lifespan but also reduces the risk of slip. Entrance matting that helps as an additional barrier against contamination from dirt, dust and moisture is certainly worth researching.

ProfilGate is just one example. It’s also the mat of choice for major UK brands, and is proven to;

|

|