When it comes to recycling and being better at it, I think we’re all on the same page. That page is all about how we can make real changes to waste management and how, as businesses, we play a part in the wider environmental issues we face.

The drive for continuous improvement in cleanliness and recycling, in the most effective way, is ever growing and we are seeing a rapid increase in uptake of a more evolved waste management process. Here are some examples of how others have embraced recycling to help them achieve their business goals.

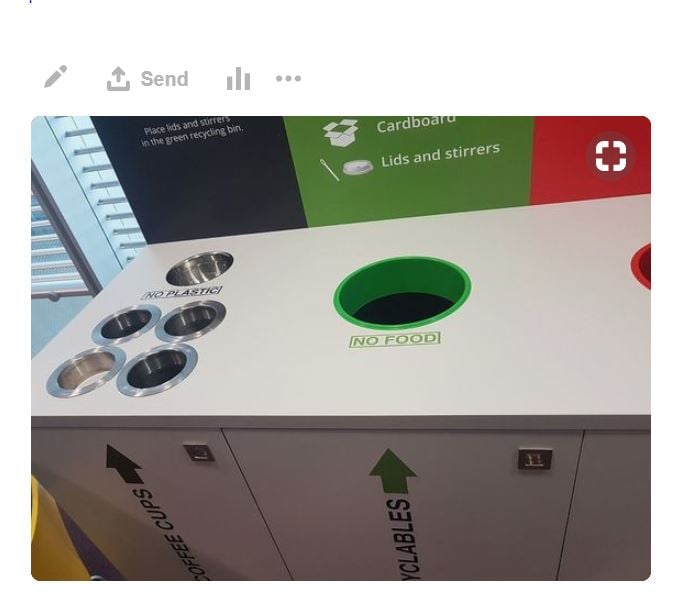

1- Introduce recycling solutions that encourages correct waste separation

Continuous improvement in waste separation is a real win:win situation. In business terms, correct waste separation reduces the cost of waste. In environmental terms, it increases the volume of waste classed correctly and therefore reduces the chances of your waste (albeit with best intentions) ending up in landfill.

Here’s a great example of how you can achieve the business and immediate environmental benefits referenced above, but also help educate better waste management to your staff, your customers, your visitors – helping to encourage positive recycling habits.

2- Introduce a recycling solution that reduces the use of plastic

Since the introduction of the 5p charge, the use of single-use plastic bags has reduced 80%. It’s worked so well that a 5p charge on single-use plastic bags will be extended to corner shops and smaller retailers. But how can your business reduce its reliance on plastic rubbish bags?

The production and manufacturing of plastic bags (much the same as a typical single-use carrier bag) come at a cost – Co2. If you can reduce the amount of plastic or plastic bags you use, your Co2 footprint will improve.

Here’s how a cafe has adopted Longopac – a continuous bin liner system that by design reduces bag usage by 6-7 times.

Let’s do some maths to see why Longopac helps not only reduce CO2 emissions but reduces plastic bag waste.

Let’s assume, for simplicity, your business uses one 125L plastic rubbish bag a day, every day for a year. That’s 365 bags or 24kg of plastic and an equivalent CO2 emission of 72kg.

On average a bag is only 60% full before it’s emptied – wasting plastic. With Longopac, the bin is always 100% full when emptied hence reducing plastic consumption to 9kg and CO2 emission to 23kg.

CONCLUSION:

If you are making lean improvements to your business, your production line or manufacturing process, why not your recycling and waste management?