You don’t have to be listed on the London Stock Exchange, officially listed in a European Economic Area or admit to dealing on either the New York Stock Exchange or NASDAQ to care about sustainability.

That said, businesses of all sizes, as they step ever closer to 2020, may struggle to find new ways to support their final push towards their ‘sustainability’ goal.

You could liken the journey to 2020 to a marathon. You have to break it down mile by mile. And in the final few miles, you may hit the wall. In the world of 2020, your ‘hit the wall’ moment is where you may look for simple gains, the everyday process you previously overlooked. These simple solutions may just get you over the finish line.

Here’s where keeping it simple, stupid (KISS) comes in. Making those final small steps towards sustainability does not need to be complex, complicated or even costly.

Here are just 5 simple, yet very effective, sustainability solutions to consider.

Whilst the demand for change may be driven by law or peer pressure, your employees also have a part to play. What measures have you put in place to support sustainability in the workplace?

#1 – Conscious & Unconscious Waste Segregation

Linking back to a previous blog, which focused on the psychology of recycling, we explored how design, identity, convenience, association and influence can effective positive recycling behaviours – leading to improved waste segregation.

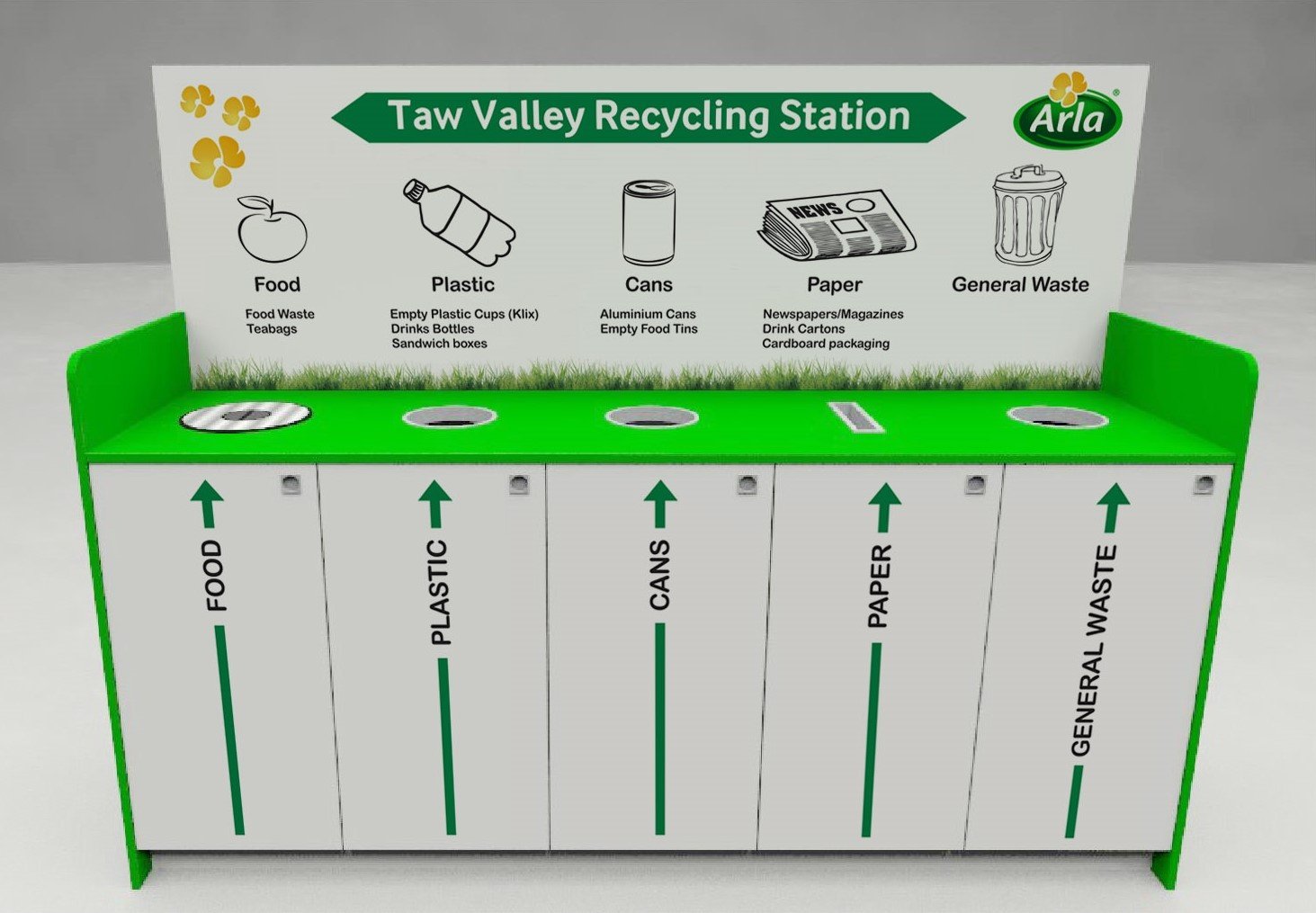

| Design / Identity – go bespoke with a recycling station / recycling hub incorporating your brand colours / logo

Association – In one example (see right), going bespoke allowed the brand owner to be bilingual, supporting association with those in a geographical area Influence – otherwise known as the nudge theory, go bespoke and visually influence positive recycling habits

|

|

#2 – Signpost your waste and recycling bin/s for, what could be, the most simplest of tools to promote positive recycling behaviours

| Simple measures such as signposting recycling hubs / bins is proven to not only increase recycling rates but also improve waste segregation. Improved waste segregation at source, is not only your responsibility as a producer of waste but it also helps reduce costs.

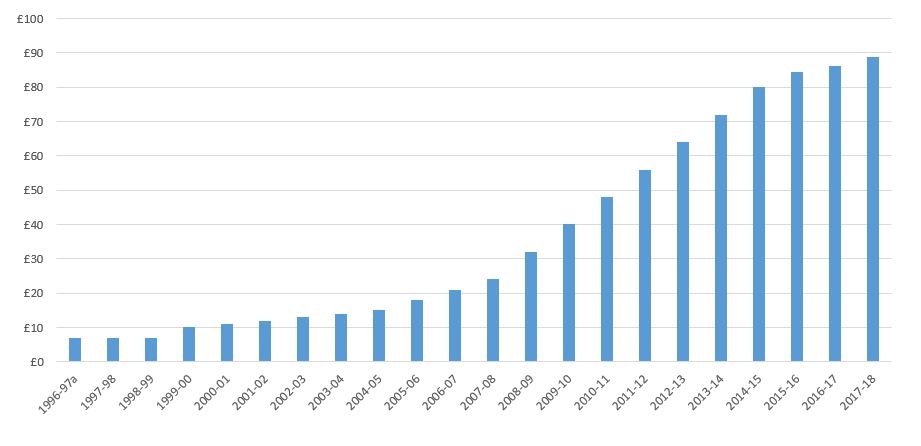

You only have to look at the significant increase in Landfill Tax (which as a business owner is passed onto you) to see how making recycling at work easy can directly impact the bottom line. |

|

Landfill Tax – ££ per tonne

#3- Improve Process To Drive Productivity Gains

A gain, no matter how small, can make a difference especially if you have a lot of employees. Saving even seconds off a process by adopting LEAN principles to (A) how your employees management their own waste through to (B) how your cleaning teams managed its removal adds up.

Example A: Streamline Your Employees

| Whether you position individual bins together or invest in a recycling station / hub, the order in which the apertures are positioned will affect how long the process takes. Let’s think about a meal deal (sandwich, a drink and a packet of crisps). In what order should the apertures be to create the optimum lean process? Our recommendation would be: Food Waste and/or Liquids, DMR (or more specific recycling apertures) and finally General Waste. Placing general waste on the end also helps drive down waste to landfill / incineration. |  |

Example B: Streamline Your Cleaning Team

Adopting processes that provide a ‘no waste contact‘ solution removes the need for single-use (typically non-recyclable) gloves being used in each cleaning area. Again, a small gain but they quickly add up.

“It is much easier and more hygienic to ‘empty’ the bin stations. The no waste contact means the janitor no longer has to wear gloves when removing/changing the bags as the new process means no actual contact with the bag contents”.

#4- Incorporate products which, by themselves, reduce carbon footprint

Aside from using recycled paper inc. in your photocopier or even your washrooms, have you looked closely at the products you use throughout your waste management process?

| Bin liners for instance. Biodegradable and compostable liners are common place, but have your considered liners made from virgin plastic.?

Longopac, for instance, is manufactured from three-ply polyethylene- low material consumption virgin plastic. Independent life cycle analysis shows that it uses 1/3 less carbon dioxide compared to traditional liners. |

|

#5 – Incentivisation

When all else fails, consider ways to incentivise your workplace to recycle. Solutions for bottle deposit returns schemes, sometimes referred to as reverse vending, have been in existence for some time now. Thankfully, the UK is waking up to the idea and some businesses have adopted it into their workplace. There are a number of solutions available, some compact, some collect & sort but one common aspect is the ability to incentivise the return of a single-use item (be it a plastic bottle, a coffee cup or a drinks can) in exchange for something of value – money off token, hard cash, charitable donation etc.

| In this example, CafeCrush™, offers an on-site solution for the return of single-use plastic bottles, cups (inc. coffee cups) and drink cans. Available as a compactor (plastic bottles, cups and cans) or a shredder (cups).

As a compactor or shredder, CafeCrush™ also has a consequential benefit of dramatically reducing waste volume by up to 90%. Yet another tick in the box for solutions to help support a reduced carbon footprint. |

|

Keen to learn more?